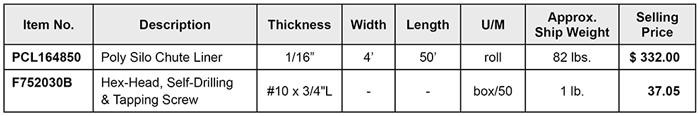

POLY SILO CHUTE LINER

-

An economical and easy way to repair rusted out silo chutes

-

Simply unroll and pull up silo for seamless one-piece, economical installation

-

Slick, smooth surface provides fast feed discharge — prevents feed hangup — silage won't cling to finish

-

White poly liner will function for chute skylights... by cutting 12" square holes in steel chute every 6'

-

Poly liner is extremely tough — resists cold, and warpage. UV stabilized to help withstand sunlight (through holes in old chute)

-

High-strength polyethylene (pronounced poly-ethel-lean) is lightweight and much more durable than steel or fiberglass

-

Long-Life, high-density poly is non-porous — resists moisture, silage acids, feed additives and other chemicals

-

Superior performance has been proven — used for years in heavy-duty industrial applications (meets FDA Regulation 121.2501)

- Use a chalkline and strike a center line from the top to the bottom of the chute.

- Mark the center on both the top and bottom end of each liner.

- Beginning at the bottom of chute, install first liner, Line up center markings on liner with chalkline on chute.

- Secure liner to chute using standard 3/4" length self-drilling and tapping, hex-head screws as required — insert through liner into chute using a screw gun (liner can also be pop-riveted to silo chute).

- Install screws about every 8" to 10" along both sides of liner.

- Install remaining liners, lapping joints 1" in direction of feed flow (to prevent feed hangup).

- Cut top piece of liner, if required, using any standard power or hand saw.

Click the image below to enlarge